The Patented DBAR Adjustable Grain Cushion Box

Finding reliable, cost-effective ways to minimize grain damage poses an ongoing challenge for the grain handling industry. LCDM offers an innovative DBAR adjustable cushion box that’s revolutionizing the grain flow equipment industry.

The DBAR features a patented design that reduces grain damage by more than 50 percent — and in some cases, the box eliminates damage entirely. Less grain damage means a more productive and profitable operation.

Quick facts:

- Stock sizes: 8”-18”

- Replaceable inner component parts

- Oversized service door

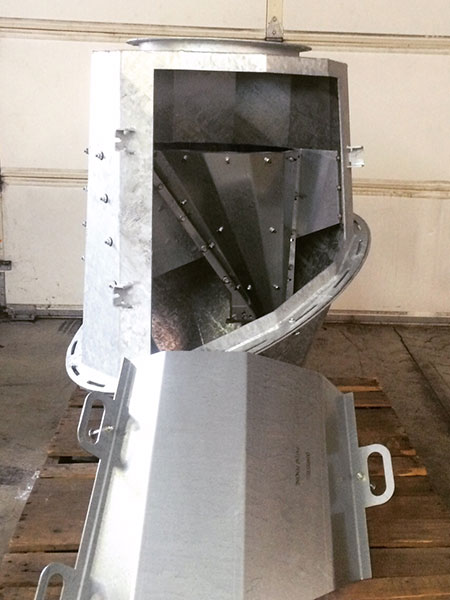

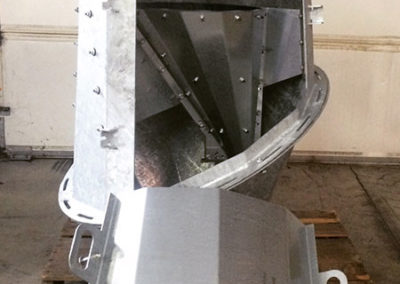

- Heavy duty, 8-gauge body with a hot dipped galvanized finish

- Liner options:

- Urethane

- Ceramic tile

- Kryptane

- Other liners available upon request

What Is a DBAR Grain Cushion Box?

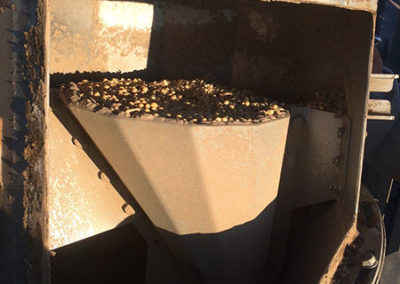

DBAR stands for dead box adjustable round. This unit features an internal cone with an adjustable baffle that collects and cushions grain — even when the spouts aren’t running at total capacity. You’ll experience a consistent pocket of grain and generate a higher-quality product while running your operation efficiently.

The design also contains a larger upper service door and a lower inspection door that provide easy access and enable fast cleaning and maintenance. The unit’s oversized body allows maximum cone fills that create the optimal cushion.

DBAR Adjustable Grain Bin Cushion Box Features

Some of the more prominent DBAR cushion box features and attributes include:

- Adjustable baffle: An adjustable baffle allows you to customize the level of cushion for the grain to meet your specifications.

- Versatility: The cushion box’s construction works well for full or partial-capacity situations.

- Durability: The heavy-duty 8-gauge body with a hot dip galvanized finish ensures reliable, long-lasting performance in all operating conditions and environments.

- Easy maintenance: Two conveniently located oversized service doors make cleaning a breeze. Checking for and removing foreign objects, dust and debris is a fast, straightforward process.

- Liner options: A wide variety of liner options are available, including blue urethane, Kryptane and Extreme Green.

- Replaceable parts: Replace inner components as needed to ensure a long service life for the cushion box.

- Extensive size range: Stock sizes range from 8 to 20 inches

- Fast installation: The box is easy to set up with minimal time and labor required for installation.

- Convenience: The design eliminates the need for flow retarders in the middle of the spouts, contributing to the ease of installation for the millwright.

The DBAR is ideally suited for grain-on-grain cushion box applications where the grain legs are not operating at total capacity, as well as for times when you need to vary the capacity of the spout between full and half-full. The self-cleaning inner cone also produces excellent results during operations with a high risk of cross-contamination.

DBAR Liner Packages

Using the ideal liner for your cushion box allows you to extend the overall life of your unit. Keeping several extra liners on your shelf allows easy replacement during an emergency without additional downtime. We send you all the necessary hardware for quick and easy liner installation.

Our three liner options are:

- Low-grade: Blue ¼-inch urethane

- Mid-grade: Red ¼-inch Kryptane

- High-grade: ¼-inch Extreme Green

“When we heard about the patented DBAR by LCDM we were skeptical it could make much of a difference. After installing one at our customer’s facility, results were impressive. Damaged grain was reduced thereby providing greater profits. We plan to use these on every install”

BryanHow the DBAR Grain Cushion Box Beats the Competition

No competing cushion box on the market can match the DBAR’s versatility and quality — not to mention the ability to minimize grain damage. While most models only provide grain cushioning when they run at total capacity, the DBAR adjustable cushion box offers the same benefit for operating at reduced volumes. A standard cushion box cannot produce a sufficient cushion to protect the grain. You can use this option for a broader range of applications without concerns about material damage.

Cushion Boxes for Unmatched Grain Quality

The most essential DBAR cushion box benefit to a grain business owner or project manager is the superior quality of the grain. You’ll lose less product to damage, making your entire operation more efficient and cost-effective. You’ll also get more usable grain at a lower expense, which will positively impact what matters most — your bottom line.

Custom Grain-Handling Products at LCDM

At LCDM, we recognize that all grain-handling operations are unique. We have the expertise and resources to develop a custom grain cushion box matched to your specifications and applications. The DBAR grain bin cushion box is the culmination of decades of material handling research and development that have made us an industry leader.

Our team includes in-house SolidWorks-certified 3D design professionals who can transform your concepts into a fully functional solution that meets your operational requirements. We can also provide engineering support for your job site layouts to optimize efficiency and productivity. Moreover, we’ll deliver unparalleled technical support during every phase of your project.

Revolutionize Your Grain-Handling Processes With LCDM’s DBAR Cushion Boxes

At LCDM, we’ve recognized and filled the need for improved design and engineering of grain flow products. Our advanced adjustable cushion box for grain quality is one example of the many solutions we offer to improve your operation’s production and efficiency.

Discover how the DBAR and our other products can help you improve your results in your operation. Contact us for more information and a no-obligation quote today.

“We tried the new LCDM cushion box on the two longest runs, experienced much less damage, then changed out all of the old cushion boxes. The following year, the owner informed us that they were very happy with the results. The reduced damage paid for the change out many times over in just one year.”

DickSee our customers’ thoughts on our cushion box in the testimonial section!

In addition, check out the DBAC cushion box.