Dust Suppression Hopper

Dust Suppression Hopper

You need the proper technology to keep operations in order when you manage an industrial environment. If you’re looking for a way to create a happier, more efficient workplace, why not try a dust control system from LCDM? We offer Dust Suppression Hoppers, which are a Dust Supression System designed to keep harmful dust production to a minimum while offering the protection you need to do your best every day.

What Is a Dust Suppression System?

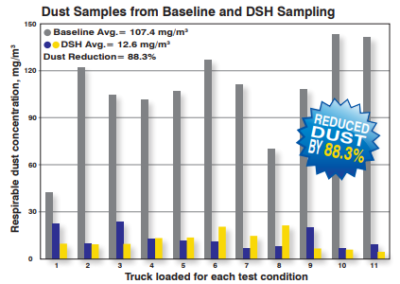

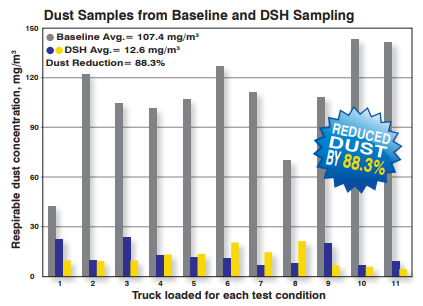

The dust reduction products are designed to surpass conventional loading equipment in terms of safety, productivity and longevity. A Dust Suppression Hopper acts as a grain loading spout that can be easily installed under a feed point. As the Dust Suppression Hopper is filled, it removes the air from the product and speeds up loading times.

These systems can drop dry goods into almost any receptacle, including trucks, bags, storage containers, railway cars and more. Thanks to an efficient transportation process, the dustless loading spouts can eliminate the majority of dust for some of the biggest loading applications.

Benefits of Dust Suppression

Dust suppression systems from LCDM can make your life and the lives of your

Dust Suppression Hopper

team members much easier. In the long run, these systems will help enhance your daily routines while making each loading process a more pleasant experience for everyone involved. Some of the benefits offered by a Dust Suppression Hopper include:

- Improved safety: We understand how important safety is to your organization. What makes dust such a major hazard is that too much of it in the workplace can increase the possibility of a fire or explosion. Meanwhile, dust also reduces overall visibility in the environment and increases the likelihood of other accidents. Why leave these risks up to chance when you have the power to protect operators with dust control and loading systems? Dust suppression equipment will put your mind at ease and make everyone feel safer.

- Increased profit: Up-front cost is only a small factor to consider when you upgrade to new technology. What truly matters is what your organization stands to gain down the road. Thanks to the improved safety and efficiency offered by our dustless loading spouts, you’ll be able to reduce downtime and product losses as a result of inconsistencies or accidents. Less dust also equals less time and money required for cleaning and maintenance.

- Environment: Did you know that dust produced by industrial operations is a major cause of air pollution and environmental hazards? In today’s world, it’s more crucial than ever to find new ways of protecting the environment. By producing less dust, you’ll preserve air quality and ensure you’re doing your part to take care of the planet and your community!

Dust Suppression Hopper Versus the Competition

If you’re looking for a reliable dust control system, how do you decide between a dust suppression hopper system and a retractable bellow or telescopic bellow? Let’s see how Dust Suppression Hoppers measure up against the competition.

Telescopic bellows are older than DSH systems and have long been offering flexible, effective dust release capabilities. Using an enclosed system, these machines can quickly move material to the proper target containment while removing most of the dust. The greatest benefit of retractable bellows is their flexibility, which allows them to work with a variety of industries and specific applications. On the other hand, these dust control machines also have several drawbacks, including:

- Complex dust release procedures

- Inefficient operational controls

- Heavy maintenance and cleaning needs

All these factors can slow down processes and lead to profit losses. While telescopic bellows provide respectable dust control, a Dust Suppression Hopper is the superior choice for several reasons.

Unlike conventional loading equipment, Dust Suppression Hoppers are placed right under a feed point and directly above the destination. Because all the internal components are stationary and there are no extra wires or electrical parts to worry about, DSH systems are much easier to manage than retractable bellows. In addition, the equipment forces the air out of the product while most of the dust is removed and placed inside the material column.

By the end of each day, a Dust Suppression Hopper will leave you with all your products in their proper places and with much less dust cluttering up the area. This is what allows our grain loading spout equipment to stay ahead of the competition and provide safer, smarter dust control.

Why Choose LCDM for Dustless Loading

We know you’re on a tight schedule, so we make it our mission to keep our service timely and reliable. When you work with LCDM, you can rest assured that you’ll receive a safe, high-quality product. If you’re interested in learning more about DSH or our other specialized services, contact us online today, and we’ll develop a plan to help you achieve your goals! Contact us for special pricing!