Inline Flow Retarders — What Is a Flow Retarder?

Inline flow retarders are used to slow the flow of grain in any grain system. Many flow retarders that exist in the market today include baffles that consist of thick plates. The purpose of these baffles is to establish a cushion for the grain which, in theory, should minimize the risk of grain damage. What the market has learned over the years is that this is not the case, but rather flow retarders in the market today can actually create more damage to the grain.

Quick facts:

- Stock sizes: 6”-14”

- Painted and galvanized finishes

- Liner options:

- Urethane

- Ceramic tile

Benefits of an LCDM Flow Retarder

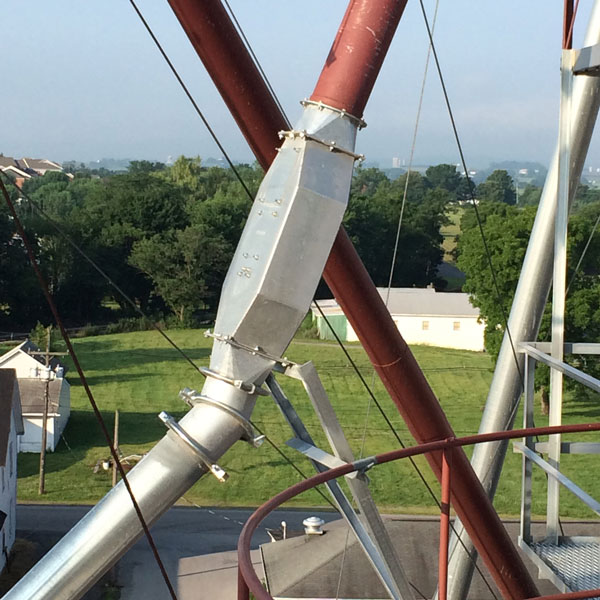

LCDM manufactures both angled and vertical retarders which are used on long spout runs. Our flow retarder has two main features: a “W” style baffle to collect grain and an adjustable baffle for self-cleaning. The adjustability of the baffle allows you to customize the flow retarder to your needs. For example, if you’re looking to achieve maximum clean-out, you can open the baffles all the way. Conversely, if attaining optimum grain cushioning is your objective, you can easily close the baffles.

LCDM offers two types of flow retarders: Inline Flow Retarders (for vertical spout runs) and Welded Sleeve (for longer angled spout runs). LCDM Flow Retarders are unique from others in the industry because they actually cushion the grain. Existing flow retarders in the market have thick baffles that do not create a cushion for the grain which can lead to grain damage. Our grain flow retarders will give you the flexibility to allow for self-cleaning in full-flow applications, as well as for complete flow restriction in low-flow applications where maximizing grain quality is paramount.

Give Us a Call at 888-963-9145

Pairing an LCDM Flow Retarder With the DBAR Cushion Box

LCDM flow retarders were designed in parallel with the DBAR adjustable cushion box to ensure the formation of a pocket of grain, which leads to better grain quality. The DBAR features an internal cone that cushions the grain when it’s running at full or partial capacity. You can combine the DBAR with an inline flow retarder to achieve superior cushioning results. However, in many cases, the DBAR makes flow retarder elimination within the middle of the spout possible.

We Can Provide Complete Flow Retarder Support

With four decades of grain and material handling equipment expertise, LCDM is a company you can trust to provide a fully supported inline flow retarder solution that we can customize to your operation and applications. Our services include 3D grain system design that can bring your unique design concept to life. We can also assist you with engineering and jobsite layouts to maximize the performance of your flow retarder and setup.

Contact LCDM Today to Explore Your Inline Flow Retarder Options

Feel free to contact us to learn more about how our advanced flow retarder and DBAR cushion box solutions can benefit your grain handling operation. We’ll also be happy to provide a no-obligation quote.