It is a long journey from the fields of the farm to the product on the shelf. Included in that is also a long list or processes, especially for versatile products like grain. Some grains make it through within their natural form, while others get churned up into cereal, pressed into oils and mixed into batters. The grains are handled and stored every step of the way, then handled again.

It all starts at the farm when it gets harvested. After it is plucked from the plant, grains have to be washed and dried to prepare them for storage. Any moisture or impurities that are not caught at this stage can potentially ruin the entire harvested collection. Once processed, the grains are moved to further storage facilities, which will be moved into their individual product line.

The storage facilities have to have a specific temperature to preserve the grains and maintain moisture control, aeration and regular monitoring. The handling equipment combines elevators, conveyors and augers to move the grain without causing damage. The lining comes in with the preservation of the grain, which is used in the various storage facilities.

The Role of Linings in Preserving Grain Quality

Storage bins, silos, conveyors and chutes all have linings to preserve the grain quality and improve the efficiency of movement in grain handling and storage. Here is a breakdown of all the various functions:

- Protection against wear and tear: Grain handling is always in large volumes, which move at high speeds from one area to another. Often, a surprising amount of wear and tear can happen as, although the grain is hard and durable, it is small and constantly collides with other hard, durable grain. The linings provide a layer of protection for the grain as well as for the machinery and equipment in use.

- Moisture control: Grains can bring in an element of moisture into direct contact with the handling equipment, especially if they have just been cleaned. Moisture can result in slow corrosion if not attended and it goes unnoticed. The lining prevents it by creating a barrier.

- Grain movement: LInings provide a reduction in friction within the handling equipment. The grains are able to move smoother and more efficiently.

- Temperature control: The lining can provide an insulation layer for storage units, allowing for better temperature control.

- Reduced maintenance and cleaning: Linings can be changed and replaced, protecting the storage units and equipment from grain residues that could become a source of contamination.

Overview of Urethane and Polyurethane Materials

There is a difference between these two materials, but both are used as lining options for grain handling.

Urethane as a Lining

Urethane is also known as ethyl carbamate — an organic compound valued for its abrasion resistance and durability. It is less ridge than metals and has flexibility and impact absorption, making it a good material for dealing with grain. Urethane is often used as industrial coatings and linings and also for parts like seals and gaskets.

Visually, urethane looks like a type of plastic. It is part of the polymer family, which makes it part of the plastic family, although more like a distant cousin. It can be molded into various shapes and forms and depending on its composition, it can either stay in a soft, flexible format or be a hard, ridged type.

It is created synthetically from chemical processes that use isocyanates and polyols, which you get from petrochemicals. Although you might think because it is an “organic” compound, it has natural sources, the term organic is very different in chemistry from our everyday use. The term “organic” in the science field merely means that it has a carbon molecule compound.

Polyurethane Materials in Agricultural Applications

Polyurethane comes at a higher initial cost than urethane and it is basically taken one step further. Although many people use the two terms interchangeably, there are differences between the two types of materials. Polyurethane is composed of organic units that are joined together by urethane. The result is a material with a wider range of flexibility, rigidity and density. You might find it as a foam-type substance, like you get in upholstery, or as a tough insulation panel. You can use it in wheels, tires, adhesives and coatings.

The material has a high durability rating and is resistant to chemicals and moisture. Within the agriculture sector, polyurethane can be used to make seals and gaskets for farming machinery. It can also be used for tubing, hoses, wheels and tires.

Polyurethane is often used as a lining material to protect the stored grains from moisture and pests, as well as on conveyor belts to reduce friction. There is an increased interest in creating polyurethane with bio-based resources instead of fossil fuels. Scientists are still working it out, but the research looks promising.

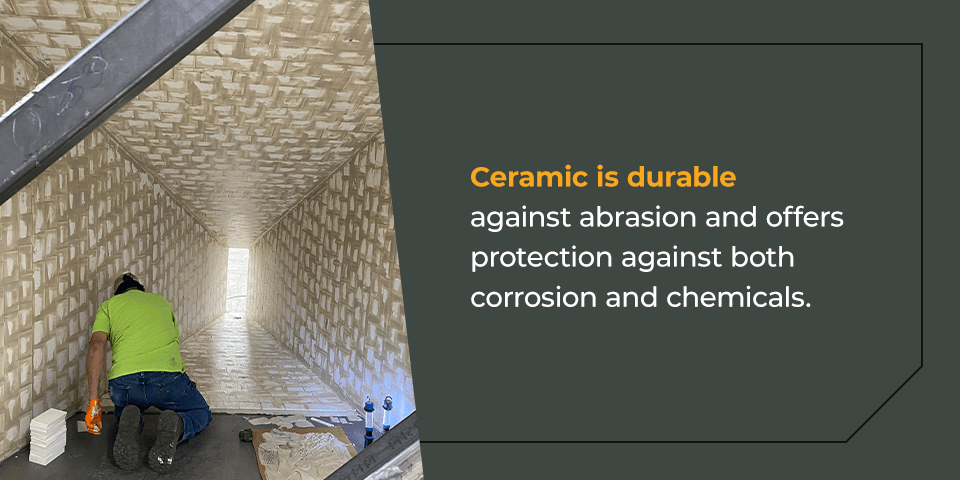

Ceramic Options

Ceramic lining is another popular option as it has a unique advantage with resistance to wear and tear and a high level of durability. Ceramic is durable against abrasion and offers protection against both corrosion and chemicals. It is also good against high temperatures, which can come from a fast-moving conveyor belt engine. Its hard, smooth surface also means low maintenance.

The linings are used within the interior of a storage bin and silos to protect against wear and tear. The storage bins have a longer lifespan as they now have this protected layer. Ceramic is also a natural occurring product, which means it offers a lower environmental footprint than other options.

Urethane and Polyurethane Materials vs. Ceramic

Let’s look at these materials head to head:

- Flexibility: Polyurethane offers more flexibility than ceramic. Its polymer compounds give it absorption qualities that ceramic doesn’t share.

- Chemical and temperature: Both materials are highly resistant to temperature changes and are chemical resistant. Ceramics can withstand it, technically better, but for the use of linings, both are adequate.

- Installation: Ceramics does require a little more effort to line chutes and so on than urethane and polyurethane. However, the ceramic is less maintenance.

- Cost: Urethane is the cheapest. Polyurethane costs a little more but is still cheaper than ceramic. However, ceramic has a longer lifespan and may be more cost-efficient over a longer time period.

- Environmental impact: In the future, polyurethane might have a low environmental impact if they start creating it out of biodiesel, but for now, ceramic is better in this regard. Ceramics have a low environmental impact as they are a natural material and can be recycled afterward.

Where to Get Ceramic Lining?

You can get your ceramic lining from LCDM. Depending on your needs, we also have options with vacuum-bonded liners or epoxy bonding. There are so many options for larger tiles or a hex mat ceramic, depending on what you are looking to line. Request a free quote and let us know how we can help you with your solution.